APM Terminals

Project Engineering and Embedded Solution

Overview

APM Terminals Itajaí is located in the Port of Itajaí, Brazil's second largest container port. The terminal has four berths totaling 1,035 meters. With a draught of 14 meters it can receive vessels up to 366 meters in length with a capacity of around 9,000 TEU.

The Challenge

I started in this project as a freelancer for a new venture of four other partners with multiple backgrounds that saw an opportunity to create a system to fulfill that demand. After four months of various meetings and visits to the port, working around heavy machinery and under the summer sun in Brazil that can reach 40 degrees, I was invited to be a partner.

The Solution

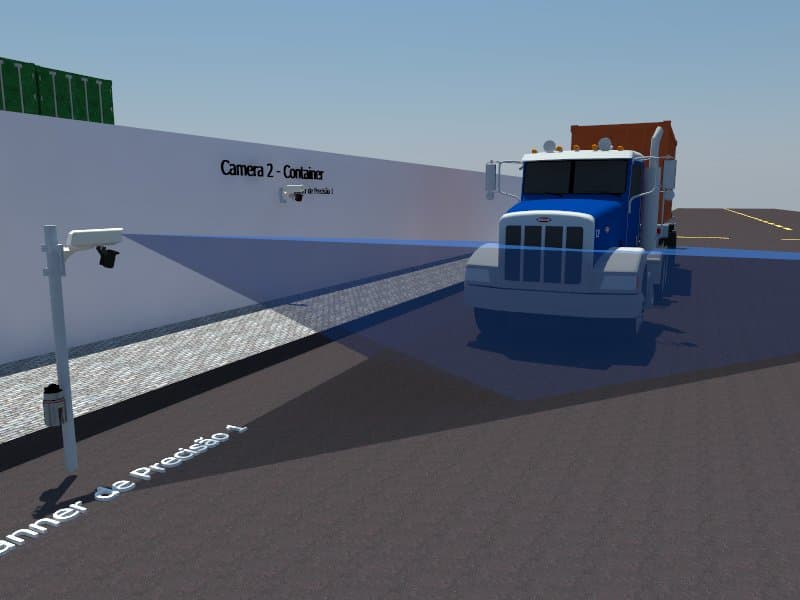

After using Google Sketchup to sketch the solution's infrastructure, I moved to code in C++ & Qt, a solution to be running on Intel NUCs placed in the entrances, receiving input from the cameras and processing the optical character recognition over the images and synchronizing that with external servers.

The Result

The solution was deployed around September 2014 and ran for a year with various iterations during its deployment. It posed a huge challenge to maintain a solution like this. In 2015 I decided to leave Brazil and move to Germany, which meant my part was sold, and later the company itself was incorporated by a rival.